Total Pageviews

Total Pageviews

Tuesday, February 25, 2014

Friday, February 21, 2014

DCSS (Delta Cryogenic Second Stage)

The DCSS has been selected as the interim upper stage for

the first two flights of the Space Launch System (SLS), according to a

justification on NASA procurement website.

Based on the responses to that sources sought synopsis, NASA

determined that the DCSS is the only means available to support the immediate

in-space propulsion needs of the SLS within the SLS manifest schedule

constraints," says the agency, “the DCSS is the only known in-space stage

requiring relatively minor modifications to enable full compliance with the

requirements of the early SLS manifest."

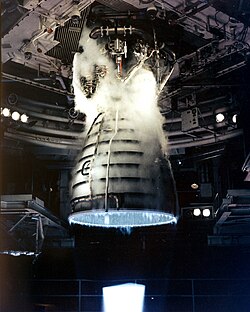

The DCSS is powered by a single Pratt & Whitney

Rocketdyne RL-10B engine, fueled by liquid hydrogen, like this one:

The rocket has divided the political and space communities,

with supporters trumpeting its unprecedented capabilities and detractors

blaming the program for taking precious dollars from NASA. In any case, NASA is

now legally required to build SLS, earning it the derisive name 'Senate launch

system' in some corners.

RS-25

The RS-25 engines are the most powerful engines in the

world. Also they will be the first reusable engines in history. They were used

30 years ago on another mission, but now they know that they are the right ones

to carry with this mission. These engines are 200 feet long and have a diameter

of 275.6 feet of diameter. They will be the main engines powering the SLS. They

will also be the only ones to function on all of the missions while the

astronauts are in space.

The RS-25 will function with hydrogen and liquid oxygen

fuel. These engines are already in Florida for trials and they are installing

new technology like new hardware and a new battery.

Each engine will be equipped with a Main Engine Controller,

an integrated computer that controls all of the engine's functions and monitors

its performance.

These engines are very sophisticated because they have

50,000 parts. The engines produce a specific

impulse for 453 seconds in a vacuum, or 363 seconds at sea

level, consuming 1,340 L of propellant per second. They have a mass

of approximately 3.5 tones and are capable of throttling between 67% and 111%

of its rated power level in one percent increments. The RS-25 operates at

extreme temperatures, with the liquid hydrogen fuel being stored at 250 °C

while the temperature in the combustion

chamber reaches 3,315 °C

After 135 missions and more than 280 hours of trials, 100%

of missions succeeded. So before using this huge engine, that is referred to

with the nickname of “Clark Kent”, they will make further trials to show this

is not only the best engine in history but also the right one for the mission.

So these engines will allow the SLS to push 73 times faster than an

Indi-500 race car.

Here are some examples that NASA gives us on their official

page to know how powerful these engines are:

The fuel turbine that is on the RS-25 is so powerful that if

it were spinning an electrical generator instead of a pump, it could power 11

locomotives; 1,315 Toyota Prius cars; 1,231,519 iPads; lighting for 430 Major

League baseball stadiums; or 9,844 miles of residential street lights -- all

the street lights in Chicago, Los Angeles or New York City.

Pressure in the RS-25 is equivalent to the pressure of

submarine experiences three miles beneath the ocean.

The RS-25 engines will be starting their final trials

after they finish testing the J-2X, at the end of November 2014.

Tuesday, February 11, 2014

Orbital Maneuvering System- Israel Olvera

Orbital

Maneuvering System

The Orbital

Maneuvering System (OMS) is basically an hypergolic propellant powered engines

that are used by the shuttle during three phases: The ascent, the orbit and the

deorbit.

During the

initial launch, the engines sometimes may be used after main engine cutoff in

order to power up or boost the shuttle to the predetermined elliptical orbit. This

is called the OMS-1 burn. But it may not be required based on the payload and

mission.

Now, the

Orbital Maneuvering System-2 burn is used to circularize the elliptical orbit

that the shuttle first enters after launch. These engines may be used to change

the shuttle’s orbital characteristics during the mission.

The Orbital

Maneuvering System engines are used to deorbit the shuttle so it may reenter

Earth’s atmosphere.

The OMS provides enough power for orbit

insertion, orbit circularization, orbit transfer, rendezvous, deorbit, abort to

orbit, and abort once around. It offers more than 1000 pounds of propellant to

the aft reaction control system.

Aft Reaction Control System

The Aft Reaction Control System is a

spacecraft which uses thrusters to provide altitude control or even

translation. It uses diverted engine thrust to provide stable altitude control

of a short/vertical takeoff and landing aircraft.

_________________________________________________________________________________

Spacecraft reaction control systems are often used for altitude control while reentering the Earth’s surface, station keeping in orbit and control orientation.

The OMS is

stored in 2 independent pods located on each side of the orbiter’s aft

fuselage. The pods also house the aft RCS (Reaction Control System) and are

referred to as the OMS/RCS pods.

Each one of these

pods contains one OMS engine and the hardware that is needed to pressurize,

store and distribute the propellants to perform the velocity maneuvers. The

vehicle velocity required for orbital adjustments is approximately 2ft per

second for each nautical mile of altitude change.

During the first OMS thrusting phase, both

engines are used to raise the orbiter to a predetermined elliptical orbit.

Next, during the thrusting phase, vehicle attitude is maintained by supporting

the OMS engines. The Reaction Control System usually does not come into

operation with the OMS thrusting period. However, if during an OMS thrusting

period the OMS supporting (or gimbal) rate or gimbal period exceeds their own

limits, RCS attitude is required. In case that just one OMS engine is used

during the thrusting period, but RCS control is also required.

Attitude Control:

It is the exercise of control over the

orientation of an object respecting the inertial frame of reference or any

other entity such as certain fields, nearby objects, etc.

During the OMS-1

thrusting period, the liquid oxygen and liquid hydrogen that are trapped in the

main propulsion system ducts are dumped. The liquid oxygen is dumped out

through the space shuttle main engines’ combustion chambers and the liquid

hydrogen is dumped through the starboard side, which is the right side. This

velocity was pre-computed in conjunction with the OMS-1 thrusting period.

Once the

OMS-1 thrusting period is completed, the RCS is now used to null any residual

velocities (just in case it is required). The flight crew operates by using a

rotational hand controller or the translational hand controller to command the

applicable RCS thrusters to null the residual velocities.

The second OMS thrusting period using both OMS engines

occurs near the apogee of the orbit established by the OMS-1 thrusting period

and is used to circularize the predetermined orbit for that mission. The

targeting data for the OMS-2 thrusting period is selected before launch;

however, the target data in the onboard GPCs can be modified by the flight crew

via the CRT keyboard, if necessary, before the OMS thrusting period.

Upon completion of the OMS-2 thrusting period, the RCS

is used to null any residual velocities, if required, in the same manner as

during OMS-1. The RCS is then used to provide attitude hold and minor

translation maneuvers as required for on-orbit operations. The flight crew can

select primary or vernier RCS thrusters for attitude control on orbit.

Normally, the vernier RCS thrusters are selected for on-orbit attitude hold.

Bibliography:

“HSF-The Shuttle.” HSF-The

Shuttle. N.p., n.d. Web, 6 Feb. 2014

“Orbital Maneuvering

System.” Orbital Maneuvering System. N.p.,

n.d. Web, 6 Feb. 2014

Monday, February 10, 2014

Hydrogen and Oxygen Fuel

What it is:

Well, in my words and what i undersrand Oxygen fuel is like

technology that burns pure oxygen with gaseous fuel. For me is a mix of pure

air and gasoline.

The Hydrogen fuel is a zero-emission fuel which uses uses

electrochemical cells. It is combustion in internal engines. It is used to

power vehicles.

How they use it on the SLS:

They use the Oxygen Fuel and the Hydrogen Fuel to feel the

OV's (Orbiter Vehicle) tank, because like I have said it, they are like

GASOLINE.

Why do they use it on the SLS?

They use it because it is a liquid-fuel cryogenic rocket

engine that was used on NASA's Space Shuttle and is planned to be used on its

successor, the Space Launch System.

How it works in general:

Well in case of the Oxigen Fuel they use it to welding and

cutting. Welding: a welding torch is used to weld metals. Cutting: a torch is

used to heat metal to its kindling temperature.

In case of the Hydrogen fuel, it operates similar to a

battery.

Bibliography:

www.nasa.gov/.../sls

en.wikipedia.org/wiki/Oxy-fuel

en.wikipedia.org/wiki/Hydrogen-fuel

inventors.about.com/od/.../ss/Physics_Illustr_2.htm

ORBITAL MANEUVERING SYSTEM

ORBITAL MANEUVERING SYSTEM

The orbital maneuvering system gives the push for the

introduction for orbit, orbit circularization, orbit transfer, rendezvous,

deorbit, abort to orbit and abort once around, and can provide up to 1,000

kilos of fuel system aft reaction control. This is in two separate sheaths which

are on each side of the fuselage aft of the ship. In

pods are also the back RCS and are referred to as the OMS/RCS pods. Each

pod contains one OMS engine and the hardware needed to pressurize, store and

distribute the propellants to perform the velocity maneuvers. The two pods provide much abundance

for the OMS. Speed required for the vehicle which deals for

orbital adjustments is approximately 2 feet per second for each nautical mile

of altitude change.

PROPELLANT STORAGE AND DISTRIBUTION

The propellant storage and distribution system consists of

one fuel tank and one oxidizer tank in each pod. Also has propellant feed

lines, interconnect lines, isolation valves and crossfeed valves. the two fuel

tanks of the OMS. Enable the orbiter to reach a 1,000-foot- per-second

velocity change with a 65,000-pound payload in the payload bay.

The propeller is in domed cylindrical titanium

tanks within each pod. Each propellant tank is 96.38 inches long with a

diameter of 49.1 inches and a volume of 89.89 cubic feet unpressurized. The dry

weight of each tank is 250 pounds. The propellant tanks are pressurized by the

helium system. Preparing count four stub galleries and a collector manifold.

The stub galleries acquire wall-bound propellant at OMS and in rcs

speed operations not to introduce by mouth gases. The stub galleries have

screens that allow propellant flow and prevent introduce gases by

mouth. The collector manifold is connected to the stub galleries and also contains

a gas arrestor screen to further prevent introduce by mouth gases also contains

a gas arrestor screen to further prevent gas ingestion, which permits OMS

engine ignition without the need of a propellant-settling maneuver using RCS

thrusters. The operating pressure of each tank's nominal operating

pressure is 250 psi, with a maximum operating pressure limit of 313 psia.

A capacitance gauging system in each OMS propellant tank

measures the propellant in the tank. The system consists of a

forward and aft probe and a totalizer. The forward and aft fuel probes use fuel

(which is a conductor) as one plate of the capacitor and a glass tube that is

metallized on the inside as the other. The front and back oxidizer probes use

two concentric nickel tubes as the capacitor plates and oxidizer as the

dielectric. (Helium is also a dielectric, but has a different dielectric

constant than the oxidizer.) The back probes in each tank contain a resistive

temperature-sensing element to correct variations in fluid density. The fluid

in the area of the communication screens cannot be measured.

One tiny electric switch in each of the

ac-motor-operated valve actuators signals the respective valves' position (open

or closed) to the onboard flight crew displays and controls as well as

telemetry. An extensive improvement program was implemented to reduce the

probability of floating particulates in the tiny electric switch

portion of each ac-motor-operated valve actuator. Particulates could affect the

operation of the tiny electric switch in each valve and, thus, the

position indication of the valves to the onboard displays and controls and

telemetry.

CONCLUSION:

The job of the OMS is to propel and maneuver the shuttle

after it has arrived in space. It consists of two smaller engines located at

the rear of the orbiter on either side of the main engines.

WEB SITIES:

-Orbital

Maneuvering System

-Propellant

Storage and Distribution

-Wikipedia

Subscribe to:

Posts (Atom)